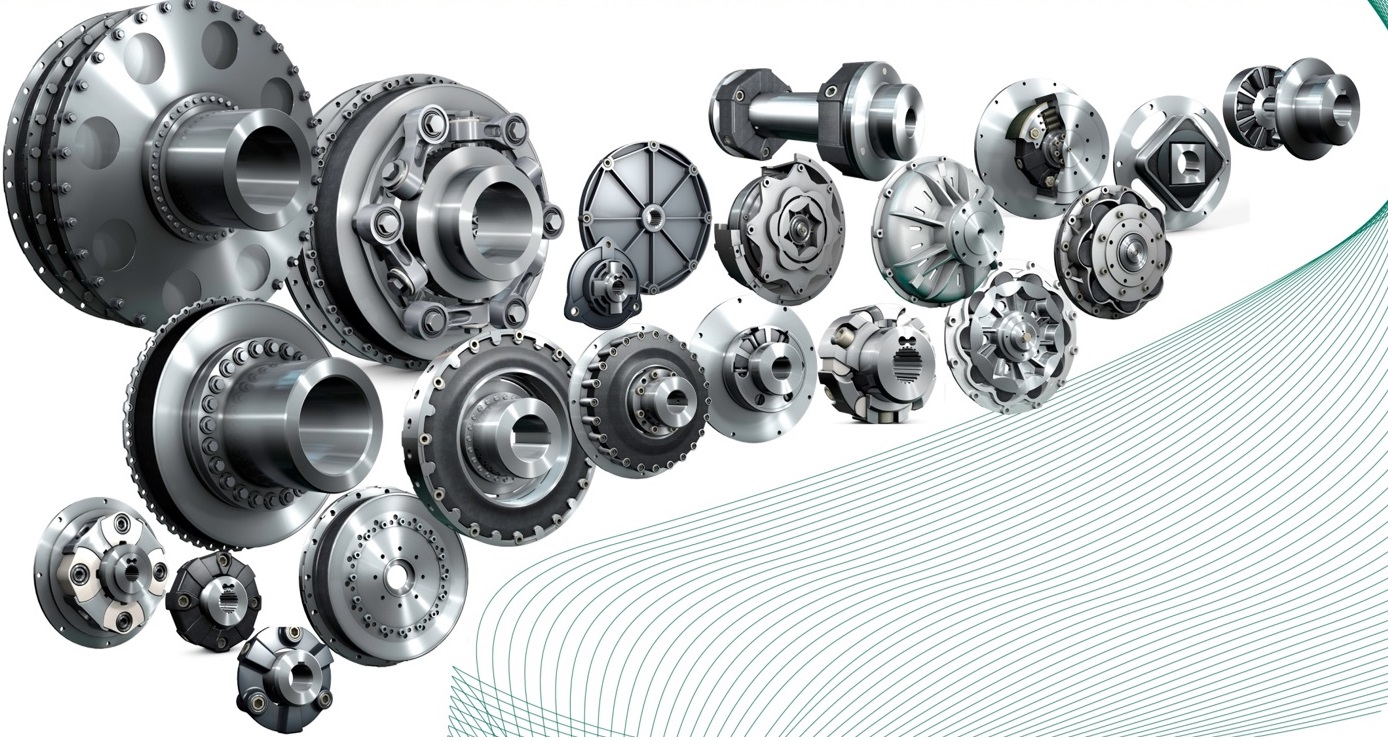

The CENTAFLEX-D couplings are very reliable, well proven couplings for generator sets, centrifugal pumpsets and other similar drives.

Within a few short years, these couplings have gained a considerable portion of the market and with more than 50.000 units in operation, they belong amongst the top ranking couplings for the gen-set market.

This range was purposely designed for Diesel driven generator and similar drives. The couplings are simple and robust in design following the well- proven design principles of the claw coupling with purely compression stressed rubber elements.

CENTA prepared selection charts for CENTAFLEX-D cou- plings to suit engines from the following manufacturers amongst others:

Caterpillar, Cummins, DAF, Daimler Benz, Fiat Aifo, Ford, GM Detroit Diesel, Hatz, Deutz, MAN, MWM, Perkins Rolls Royce, Saab Scania, Volvo Penta, VW, and etc.

In the development of the series D coupling, particular importance was given to the following criteria:

• Generous dimensioning of the rubber elements to ensure very low specific stress

• Slim configuration of the claws by attention to the material selection and by careful generation of their shape to allow a long elastic length of the rubber ele- ments. This permits relatively large angles of twist of 3°–5° at nominal torque (depending on size).

The couplings are designed as standard to mount direct to SAE standard flywheels, but in addition special designs for non-standard flywheels are readily available.

Important characteristics and advantages:

• simple, robust, safe in operation, compact, non-lubri- cated, fail safe generously dimensioned, low stress, rubber in compression elements, air cooled

• carefully tuned torsional stiffness to provide favourable torsional vibration characteristics, available with dif- ferent shorehardness elements, progressive stiffness curve

• dampens vibrations and shocks, accepts axial, radial and angular misalignments

• simple installation, even with flange mounted driven units since the couplings are „blind fitting“

• widely variable design for all standard and non-stand- ard fitting dimensions

• competitively priced and readily available from stock

Design sizes

The CENTAFLEX-D couplings comprise six design sizes for nominal torques from 250 to 40.000 Nm. This range will in practice cater for all Diesel engines from 3 cylinders upwards to include ratings up to 5.000 kW (approx. 6800 HP) at 1500 rpm.

Materials

Rubber Elements: Standard design: NBR

Special synthetic rubber compound to provide oil resi- stant, abrasion resistant elements.

Allowable temperatures: -25 up to +90°C, -50° with special material

Shorehardnesses: 50, 60 and 75. Shore A, dependant upon torsional stiffness required. Special qualities of rubber elements can be provided where sufficient quanti- ties are required.

Flange: Steel or similar material of 400 N/mm2 approximate tensile streght.

Hub: Nodular cast iron (GGG50) in Meehanite

Quality SF 500.